Floor Systems that Meet your Highest Standards

Highest endurance to mechanical influences and resistance to chemicals

The Murexin high-quality products for extreme conditions can be used in different areas – from chemical laboratories, surgery rooms, computer centers, and industrial sites to many other spaces that require floorings resistant to pressure, high temperatures, chemicals, etc.

Besides high quality, our products can also meet your every aesthetic demand.

Using different color chips, the visual effect of your flooring can depend just on your imagination. You will be amazed to find epoxy floors gracing exhibition halls, showcasing the versatility of this flooring option. We provide a practical color chart to further assist you in choosing the perfect flooring system.

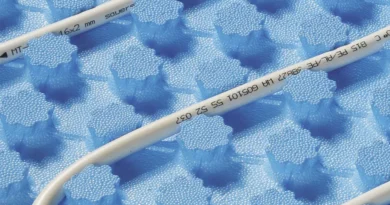

Our epoxy floors are designed with a textured surface, guaranteeing secure footing and absolute safety during use.

Depending on your demands, we offer different flooring systems.

1. Two-Coat System

Application area

Ideal for areas with light to moderate mechanical loads and the need for enhanced chemical resistance, our seamless flooring system can be visually customized by incorporating colored chips.

Usage

Ideal for laundromats, restaurant kitchens, retail spaces, warehouses, workshops, exhibition rooms, commercial premises, hospital and school hallways, chemical laboratories, industrial floors, food processing facilities, wet areas in sports arenas, locker rooms, and more.

- Surface coating

- Foundation coating

- Foundation

2. Multilayer Coating Systems

Application area

Designed for high mechanical loads, heavy point loads, impact loads, forklifts, or hand carts, our multilayer coating system provides exceptional durability. It is also resistant to chemical exposure and offers a seamless finish in smooth and rough variations.

Usage

Ideal for large-scale chemical cleaning facilities, commercial kitchens, warehouses with heavy shelving requiring forklift operation, workshops, chemical laboratories, industrial floors, high-load areas in the food processing industry, and leveling minor irregularities in the subfloor.

- Final coating

- Rough layer

- Foundation coating

- Foundation

3. Thick Layered Systems with Top Coating

Application area

Designed for the most demanding mechanical loads, heavy point loads, impact loads, forklifts, hand carts, or containers, the thickly layered systems with top coating offer exceptional strength. Also resistant to chemical exposure and provide a seamless finish in smooth and rough variations.

Usage

Usage: Ideal for warehouses with heavy shelving requiring forklift operation, workshops, industrial floors, recycling facilities, high-load areas in the food processing industry (e.g., butcheries, dairies, etc.), as well as for leveling minor irregularities in the subfloor.

- Cover coating

- Intermediary layer

- Rough layer

- Foundation coating

- Foundation

The foundation must be firm, evenly absorbent, and free from dust, grease, and oil. On such a prepared foundation, the Epoxy Primer, a two-component resin EP 70, is applied (depending on the need for slip resistance, it can be filled with quartz sand or used as is). The final layer (depending on the intended use of the floor surface) can be either Epoxy Self-leveling EP 3 or Epoxy Self-leveling EP 35, available in a wide range of colors according to the Murexin color chart.

– The Epoxy Self-leveling EP 3 is designed for areas where the final layer must be food-safe (such as dairies, food production, etc.). It is certified according to European standards.

– The Epoxy Self-leveling EP 35 is suitable for all other types of floors. It can be supplemented with quartz sand to have a non-slip surface.